- Home

- Product

- About Us

- Lost Foam Casting Process

- Lost Foam Casting Video

- Success Case

- Contact Us

This product is the main equipment for removing iron impurities in the sand treatment system of LFC production line. After the molding sand enters the equipment, iron impurities are adsorbed on the semi magnetic cylinder. Through the rotation of the semi magnetic cylinder, the impurities are brought into the non magnetic field, and slide out from the slag outlet on self weight.

Product Structure:

Magnetic seperator mainly consists of semi-magnetic drum, magnetic combination, motor speed reducer, lower box and upper box.

Main Function:

screening out the iron impurity in molding sand

The magnetic separator is to remove the dust and metallic inclusions in the molding sand. With the help of wind the micro powder and dust will be bown out and the sand will fall down to the permanent magnet pulley at the bottom. And then iron beans and other metal foreign matter will be , in order to improve the quality of the molding sand.

Product Performance and Characteristics:

1. Magnetic separation method: after sand with impurities falling into magnetic separator, due to different magnetic force in magnetic field, non magnetic sand will fall directly into the right drop outlet, and magnetic metal impurities will be transferred from the roller to the non magnetic zone and fall from the left exit.

2. Energy saving: only one 0.55KW motor can drive the equipment. Low energy consumption and high efficiency.

3. Solid equipment structure, stable operation, reduce the failure rate of equipment to a large extent.

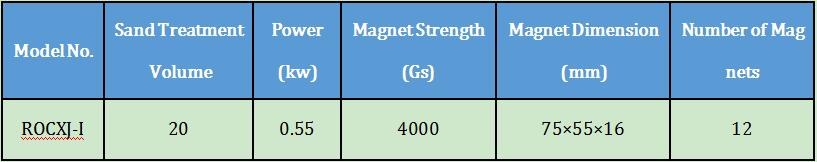

Model Selection and Technical Parameters:

(Note: the specific model is based on the actual design.)